Hydrogen-powered vehicles have the potential to address a number of challenges closely linked to the automotive industry, such as climate change, local air pollution, energy security. An R&D project in the Department of Innovative Vehicles and Materials has provided the basis for the Erasmus mobility. In 2020, our university has set a decisive research direction: the green economy, and indirectly hydrogen technology, will play a prominent role in the upcoming years. The project includes priority environmental objectives, which are to increase the social acceptance of hydrogen propulsion and to assess the environmental impacts related to storage vessel production. The problems caused by climate change are becoming increasingly pressing, so in response to the widespread societal demand for green transport, our department has set its sights on developing hydrogen storage in related research.

There are four main directions in this area:

In 2022, a joint project was launched in Northern Macedonia with Mikrosam to wrap type 4 (inner polymer core) tanks with carbon fibre. The company is one of the few that develops and sells this equipment.

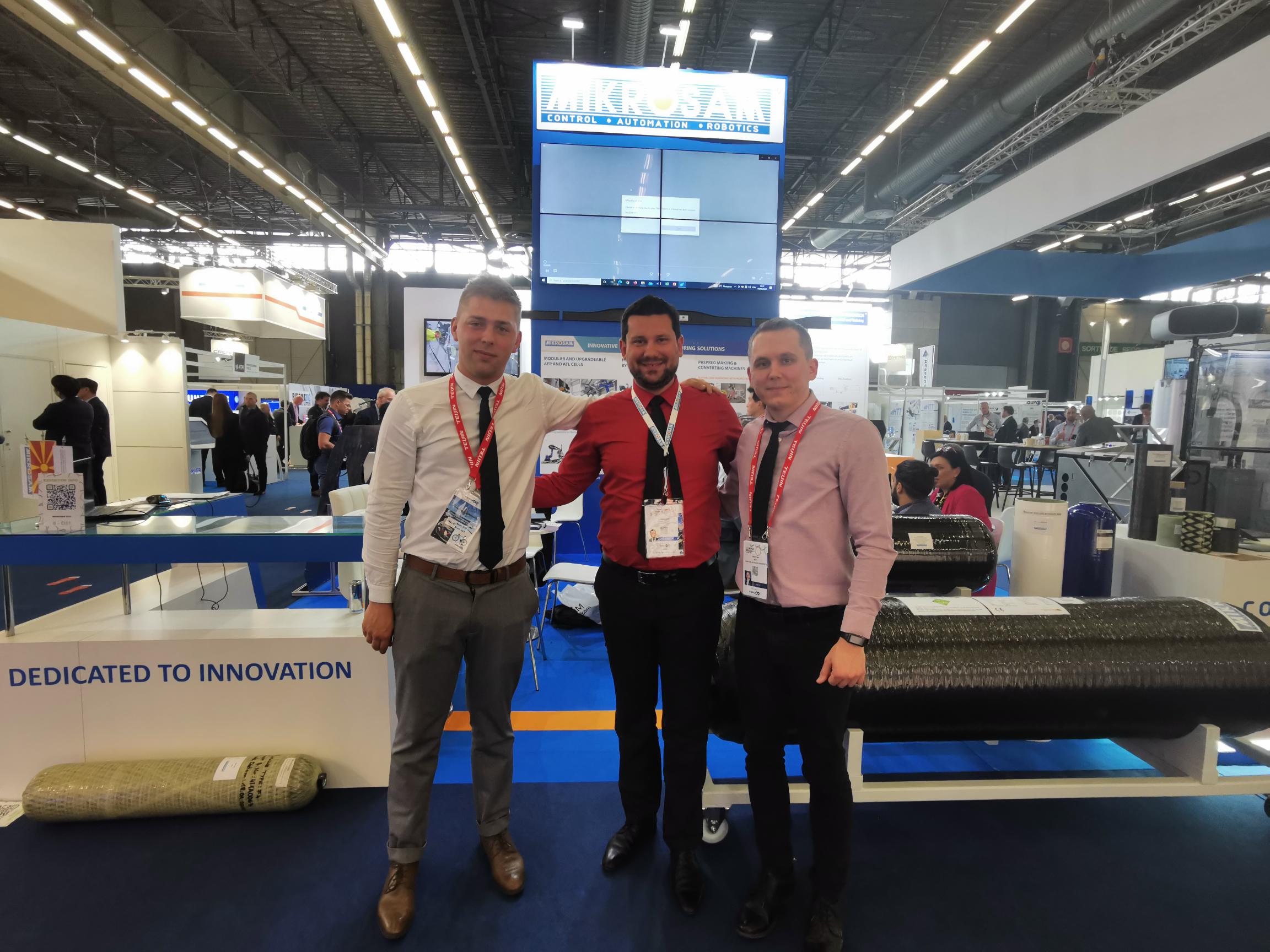

In Paris, at the JEC World Exhibition, Mikrosam presented a new development that could serve the objectives of our university. We were invited by Mikrosam to participate in the exhibition. On the company's side, we met Aleksandar Chakmakoski and Viktorija Dzingoska, who were competent in technical, management and sales areas. During the visit, we were introduced to the newly developed filament winding machine, which is capable of winding hydrogen tanks of different diameters and lengths. Having seen similar products from several companies at the exhibition, it is clear that Mikrosam is developing a high quality and outstanding product in the field. In addition to gaining insight into all areas of development, we had the opportunity to see the software for simulating the filament winding process. As a result of the successful discussions and negotiations, our university received a free trial of the software, which would otherwise have been exceptionally costly and only included equipment. The specification of the equipment for NJE's R&D work was also successfully completed.

Overall, a highly valuable business relationship was established during the visit, with further results expected in the near future.